Ensuring the safety of your workplace is paramount, and one crucial aspect of this is conducting regular electrical safety inspections. Proper maintenance of your electrical systems not only helps prevent accidents but also promotes operational efficiency.

1. Understand Relevant Regulations

Before beginning any inspection, it is important to familiarise yourself with the relevant electrical safety regulations. In the UK, the Health and Safety at Work Act 1974 and the Electricity at Work Regulations 1989 outline the legal requirements for maintaining safe electrical systems. Understanding these regulations will help you identify the necessary criteria to include in your inspection.

2. Gather the Right Tools and Resources

To conduct an effective electrical safety inspection, you will need a few basic tools and resources, including:

- Insulation resistance tester

- Multimeter

- Screwdriver

- Circuit breaker finder

- A checklist for recording findings

Having these tools at hand will allow you to carry out a thorough examination of your electrical systems.

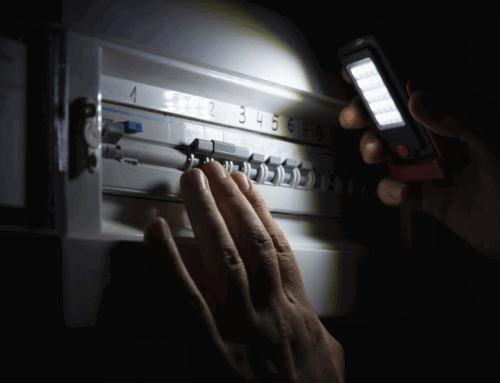

3. Inspect Electrical Panels and Breakers

Begin your inspection by examining the main electrical panel and any sub-panels. Look for signs of damage, such as rust, corrosion, or signs of overheating. Ensure that all circuit breakers are correctly labelled and functioning as intended.

Check for the following:

- Clear access: Ensure that the area around the electrical panel is clear of any obstructions.

- Proper grounding: Verify that all equipment is correctly grounded to prevent shock hazards.

- Overloaded circuits: Make sure that no circuits are overloaded, as this can lead to overheating and potential fires.

4. Examine Wiring and Connections

Next, inspect the wiring throughout the workplace. Look for any signs of wear or damage, such as frayed insulation, exposed wires, or loose connections. Pay particular attention to high-traffic areas where cables may be at risk of being damaged.

Consider the following points:

- Secure cabling: Ensure that all wiring is secured and protected from physical damage.

- Adequate insulation: Check that all wires are properly insulated and that there are no signs of moisture or corrosion.

5. Assess Outlets and Switches

Take the time to inspect all electrical outlets and switches throughout the workplace. Look for signs of damage, such as cracks or burn marks, and ensure that all outlets are functioning correctly.

Key areas to evaluate include:

- Ground Fault Circuit Interrupters (GFCIs): Verify that GFCIs are installed in areas where water is present, such as kitchens and restrooms, to prevent shock hazards.

- Tamper-resistant outlets: Ensure that outlets are tamper-resistant, especially in areas accessible to children.

6. Test Portable Equipment

Conduct a thorough inspection of all portable electrical equipment used in the workplace. This includes tools, extension cords, and any other devices that are frequently moved or used in different locations.

Consider the following:

- Visual inspection: Check for any visible damage or wear on cables and plugs.

- PAT testing: If applicable, ensure that Portable Appliance Testing (PAT) is up to date for all equipment.

7. Review Emergency Procedures

Part of a comprehensive electrical safety inspection involves reviewing your workplace’s emergency procedures. Ensure that all employees are aware of what to do in the event of an electrical emergency, such as a fire or electrical shock.

Key points to include in your emergency procedures:

- Evacuation routes: Ensure that all staff know the emergency evacuation routes in case of an electrical fire.

- First aid training: Provide training for staff on how to administer first aid in the event of an electrical shock.

8. Document Your Findings

After completing your inspection, document all findings and any actions taken. This record is essential for tracking maintenance and ensuring compliance with regulations. If any issues are identified, prioritise them for repair or further investigation.

Conclusion

Conducting a basic electrical safety inspection in your workplace is an essential step in maintaining a safe working environment. By following these guidelines, you can identify potential hazards, ensure compliance with safety regulations, and promote the well-being of your employees. Regular inspections, combined with ongoing training and awareness, will help create a culture of safety that protects both people and property. Remember, when in doubt or faced with significant issues, it’s always best to consult a qualified electrician to ensure that your electrical systems are safe and up to code. Contact us for more information.

Leave A Comment